What are all those wires for?

Sometimes I wonder where all these cables can be stuffed. ? It is a lot of them and I am not a big fan of electrical components (not to mention electronics…) But well, every sensor, switch, light, computer, etc., etc., needs its connecting kit. The wires are pressed into small gaps, crushed by other components of the motorcycle. I do not know what the KTM designers were guided by when deciding to leave a large number of cables without additional protection. Weight? Savings? Wiring in 690 Enduro requires a bit more love and attention. I do not know if other bike manufacturers do the same in their motorcycles. Possible, but I haven`t checked. ?

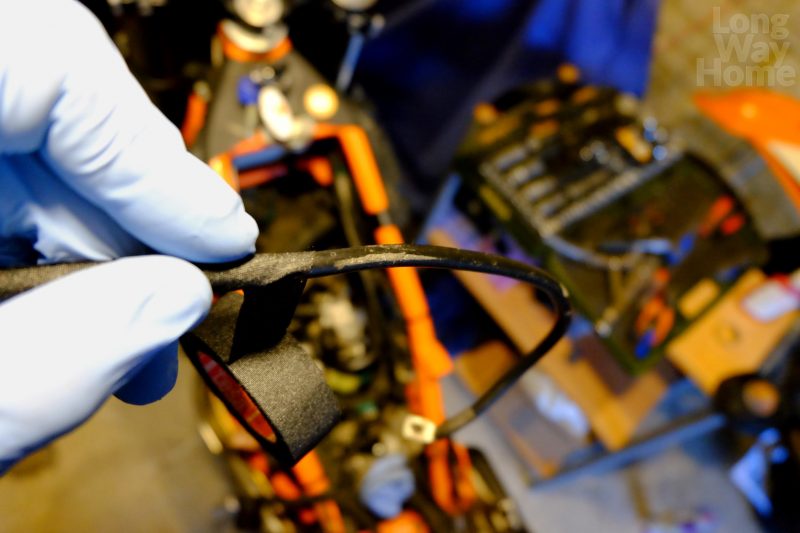

The vibrations in the single-cylinder enduro bike, while off-road, are let us admit, relatively high. The motorcycle is narrow, cables without additional lagging can rub against each another, against the elements of the motorcycle. Not to mention dust that gets in through smallest holes. Time will do its job, eventually, the motorcycle will not start and faults will show up. The wire harness in every motorcycle, regardless of the manufacturer, should be well protected in my opinion. KTM is no exception.

The tape I used for protection is TESA 51026. It increases abrasion resistance and can handle temperatures from -40 ℃ to 150 ℃. It can be easily used in places where the exhaust manifold or engine are close to the wires. I needed a lot of time to get to any cable that I wanted to additionally secure. Four pack of beer and the kilogram of M&Ms is not enough for such works as the cables are stretched along the entire length of the motorcycle. While doing it, it is good to have a service manual book at hand with the wiring diagram, because by looking at the cables, their colours and comparing with the manual you can learn the location of individual relays, sensors or connections. It’s good to do it before leaving, even if you do not want to isolate the harness. Knowing the electrical system can help identify future failures.

Some users go step further with wire harness modification. They get rid of some of the cables that according to them are not needed or step by step replace them for “more durable” ones. Not such modifications for me. I do not feel like a “specialist” to push my inexperienced fingers into such changes. I will take “a risk” and go around the world with what has been provided by the manufacturer. 🙂 In addition, I have not heard about the burned wiring at 690 Enduro, so this modification seems to be too exaggerated. And even if I wanted to try it, the constant lack of time will not allow me to.

A large part of the connectors used in KTM 690 Enduro R is unsealed. Without any problem moisture will cover the connectors, causing corrosion of the contacts. This can lead to increased temperature, problems with current flow and possible failure. While working with the harness, I tried to clean each connector with a contact cleaner. Also, I applied a small amount of dielectric grease in places where KTM did not use sealed connectors. It will help to protect the contacts from corrosion. As it is a dielectric grease, it’s a good idea to ensure that the connection between the contacts is quite tight so the current flow will not be obstructed and the connector will not slip out due to vibration.

I want to add a few things like LED lights, main light or radiator switches and heated grips, which require interfering in the wire harness. Also, I plan another important modification – voltage regulator. I will try to update the information as soon as I finish work on one of the motorcycles – provided that it will work properly. 😀

3 Comments

Erwin · 28 April 2019 at 16:51

Yes – the wiring is a bit risky but not problematic from the start. The bike uses a traditional wiring harness (meaning: no can-bus), which requires a lot of wires. I don’t like the amount of unprotected individual wires I see around the motor, close to all kinds of connectors. Not a problem when riding on the road in dry conditions, but it makes the electrics vulnerable to damage, moisture, etc.

Luki · 29 April 2019 at 17:22

Hi Erwin. I also hate amount of wires in the bike, specially those unprotected. Heard some stories from other users who had a problem because of that, that is why I decided to spend time and have a go with them. Our bikes were made in 2012, but we bought them with very low mileage. So like you mentioned, no problems from a start and it was a good moment to protect them. Also hope that grease I have used will help connectors to stay corrosion-resistant ? Time will tell.

Mark Klunder · 22 August 2020 at 19:25

I’m going through my 2009 with 44k of significant offroad kms. I found some wires with the sheathing wore off in places under the relay tray, against tank. I’ve put cable sheathing over the repairs. Hopefully i can get another 44k with these repairs. Overall I feel that the bike is reliable.